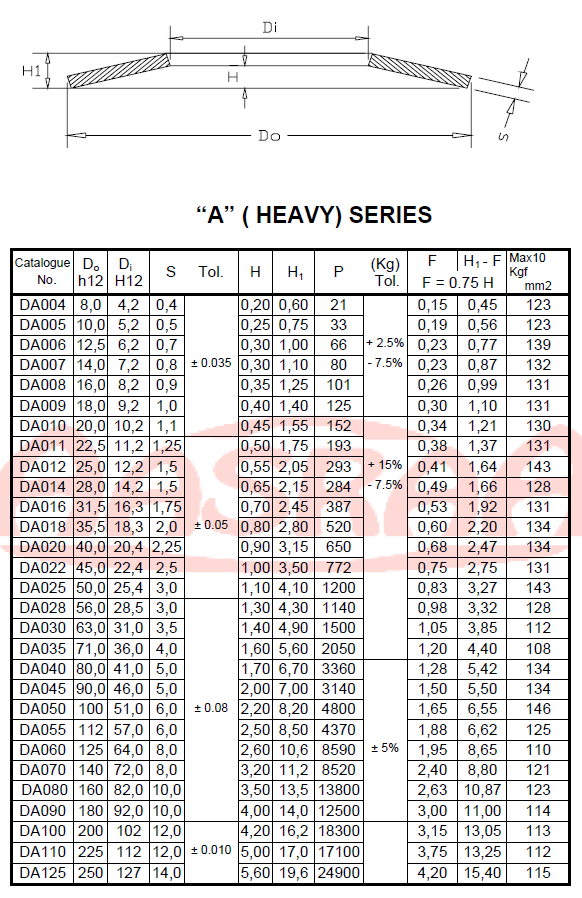

Spring Disc Washer

Introduction :

1. They are versatile in nature as alteration of load can be achieved by using different combinations of stacking and / or by varying number of discs. |

||||||||

Raw Material : Hardness : |

||||||||

|

||||||||

| Note : To achieve desired life, a positive stopper to avoid failure due to overloading, beyond 75% deflection is very essential. Spring Disc Washer arranged in stacks require a guide to prevent lateral movement under load. Guide may be located on inner diameter or on the outer diameter of the disc spring. But the internal guide is to be preferred. We also manufacture as per parties specification. Ref as per DIN : 2093 And DIN : 6796 |

||||||||

|

||||||||

| Solid Dowel Pins | Star Washers | Multi Tooth Washers | Clamps | CNC EDM Wire Cut Job Work |

| Ring Circlips | Cup Washers | Washers | RIB Washers | Wire Forms | Fasteners |

| Belleville Washers | Taper Pins | Groove Pin | Cotter Pins | Cone Washer | Clevis Pin | Circlips Auto | Hardwares |

| Belleville Springs | Ball Bearing Washers | Lock Washers | CNC Machining Job Work | Wave Washers |

| Bearing Wave Washers | Precision Machined Parts | Bearing Disc Springs | Sheet Metal Pressed Components |